IoT sensors make Industry 4.0 a commercial focus

Industry 4.0 has been a long way since creating the buzzword at the Hanover Industrial Fair in 2011.The journey to intelligent manufacturing continues, but what has really made something in recent years is the Internet of Things (IoT) and the advent of artificial intelligence (AI) solutions.

Here, it is worth mentioning that in 2012, GE coined the term "industrial Internet," which means intelligent connectivity to multiple industrial devices to create systems that can monitor, collect, exchange, analyze and provide valuable insights.Eventually, the concept of Industry 4.0 and industrial Internet began to merge, eventually reaching industrial IoT or IIoT.

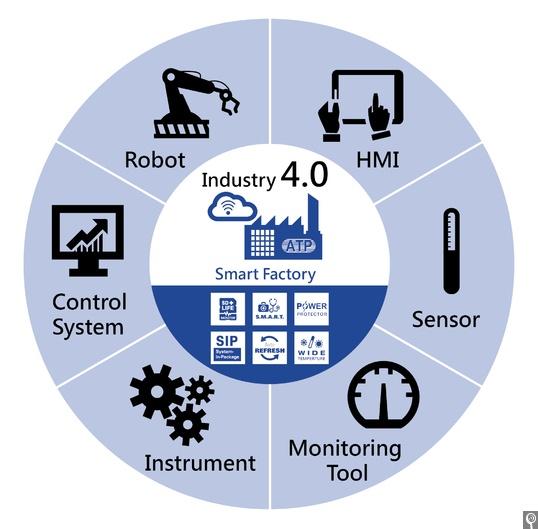

Both the so-called Industry 4.0 and industrial Internet are fundamental to achieve the fourth industrial revolution with the help of steam engines, conveyor belt and information technology with the help of cutting-edge electronic technology.It takes manufacturing and process automation to a whole new level, and the plant will build connected systems including sensors, actuators and control systems, all of which are linked together through networks of different types via the Internet protocol.

The integration of AI applications such as fault detection and classification also drives Industry 4.0.The combination of the Internet of Things and AI technology has changed the way that engineers manage data, disseminate information, and make real-time decisions in a production environment.The use of machine learning algorithms and robot-based process processing can further save cost and hours, thus further optimizing modern manufacturing.

The actual embodiment of Industry 4.0 can be seen in various GE plants.The sodium-nickel battery manufacturing plant has installed over 10,000 sensors, distributed in 180,000 square feet of manufacturing space.

All of these sensors are connected via a high-speed Ethernet network.

This moves us into one of the basic components of Industry 4.0 design: connected sensors.

Sensor Internet

Sensors connected via wired or wireless links constitute the backbone of the Industrial 4.0 or IIoT system.Machine data from sensors to the cloud is optimized for manufacturing, predict failures, schedule maintenance plans and automatically replenish inventory.

The new feature of Industry 4.0 domain sensors is the fusion of localization and communication to create precise indoor positioning systems.This allows factories to monitor tools in real time and manage workers' use to improve the efficiency, safety and quality control of assembly lines.

In the vision of Industry 4.0 at production site through end-to-end sensor solutions and services.It facilitates more informed decision making, improves operational efficiency, increased production, engineering efficiency and significant business performance.

With the Internet of Things sensors, big data and AI applications availability accelerating, the implementation of Industry 4.0 finally begins to move forward.Future factories will develop steadily through more powerful processing nodes, more automated production processes, and smarter data analysis tools capable to process and analyze large amounts of plant data in almost real time.

Previous :

Industrial Internet leads theNext :

Happy Lantern Festival