What is the Principle of a Flow Meter?

Working Principle: These meters measure the pressure drop across a restriction in the flow path (like a venturi or orifice plate). According to Bernoulli’s principle, as fluid velocity increases, the pressure decreases. The flow rate can be calculated using the pressure difference and the characteristics of the fluid.

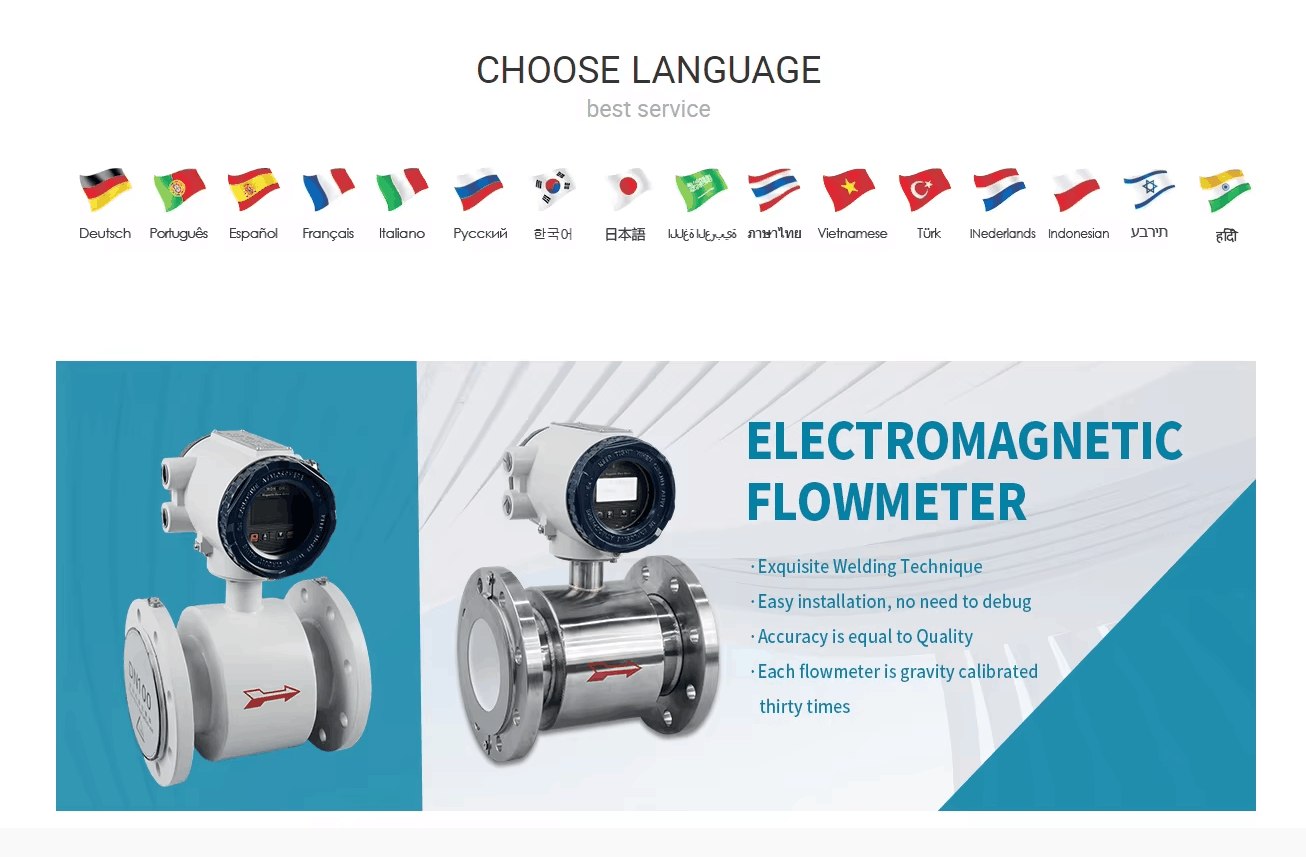

Electromagnetic Flow Meters

Working Principle: Based on Faraday's law of electromagnetic induction, these meters measure the voltage generated when a conductive fluid flows through a magnetic field. The induced voltage is proportional to the flow velocity, and by integrating this voltage over the cross-sectional area, the flow rate can be determined.

Working Principle: These utilize ultrasonic sound waves to measure flow. By sending ultrasonic pulses upstream and downstream in the fluid, the meter calculates the flow velocity based on the time it takes for the sound waves to travel through the fluid. This information is then used to compute the flow rate.

Working Principle: These meters contain a turbine that spins as fluid flows through it. The rotational speed of the turbine is directly proportional to the flow rate. By counting the number of revolutions, the flow rate can be accurately measured.

Working Principle: These meters measure the actual volume of fluid passing through by trapping a fixed volume of fluid and then counting the number of times this volume is filled. This principle allows for highly accurate flow measurements, particularly for viscous fluids.

Flow meters play a critical role in numerous industries, providing vital data for process control and efficiency optimization. Understanding their principles helps in selecting the appropriate type for specific applications, ensuring accurate and reliable measurements.