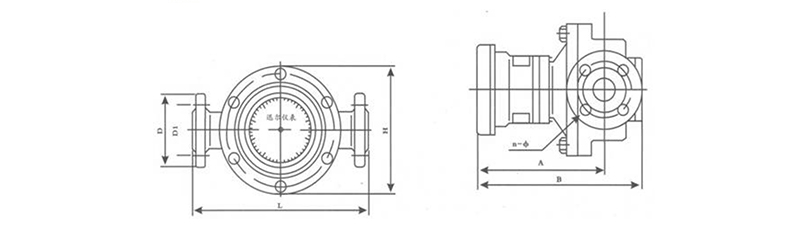

Oval gear flowmeter installation and maintenance

LC series oval gear Flowmeter is a direct reading accumulative meter. It is a volumetric Flow meter that measures the summation of liquid flow through the pipeline. Can be widely used in petroleum, chemical, medical and health departments of the flow measurement.

Oval gear flowmeter features

▪High accuracy, wide flow range and good repeatability;

▪The spiral rotor has uniform rotation, small vibration and long life;

▪It is not sensitive to the change of the viscosity of the tested liquid, especially suitable for the measurement of the liquid with higher viscosity;

▪Simple structure, small size and light weight;

▪Easy to install, no straight pipe segments need to be installed before the table.

Oval gear flowmeter installation

Horizontal installation, vertical installation.

The pipe must be cleaned thoroughly before the installation of the meter. If there is no strict filter device in the whole pipe system, the filter should be installed in front of the meter to prevent impurities from entering the meter.

The meter shall be installed at the outlet end of the pump, and the flow control valve shall be installed downstream of the meter.Open the upstream stop valve before slowly opening the downstream flow regulator or stop valve.Do not open or close suddenly.

The meter should be filled with liquid when in use.The liquid under test should not be mixed with gas, otherwise the mixed volume of gas and liquid is measured, making the measurement inaccurate. When the liquid is mixed with gas, a gas separator must be installed upstream of the instrument.

The flow in the pipeline should not increase or decrease sharply, and phenomena such as pipeline vibration, hydraulic shock and sharp fluctuation of pressure should be avoided, otherwise it will affect the normal operation of the instrument.

When the flow exceeds the specified maximum flow rate, the elliptical gear flowmeter will increase with the increase of rotating speed, and the pressure loss will increase sharply, so it should be avoided.Below the minimum flow, it can still be measured, but the error increases.The starting flow rate of the flowmeter is about 2% of the maximum flow rate, and the normal operating flow rate should be 70%-80% of the maximum flow rate.

Since the measurement of high viscosity of liquid, liquid is generally heated to reduce the viscosity, and then flow in the pipeline (both with heat preservation jacket type flow meter).When the instrument is out of use, the liquid filled in the instrument will become sticky due to cooling. If it is to be used again, steam or other methods must be used to heat the outside of the surface body, so as to reduce the viscosity of the liquid. It can only be used after the viscosity of the liquid in the instrument is reduced.Otherwise, the mucus will bite the transmission parts, resulting in instrument damage.

The temperature of the measured liquid should not be higher than the specified value, otherwise, the instrument cannot work normally, or even stuck, the counter part is easy to be damaged at high temperature.Liquid temperature variations can also cause additional errors in viscosity effects.

When each instrument leaves the factory, it is calibrated with no. 0 diesel oil at room temperature. At room temperature, the viscosity of the oil is about 3mpa.s. if the viscosity of the liquid used by the user is greatly different from this, the gear ratio or flow coefficient shall be adjusted.

Forbidden line to sweep steam and water through the meter.

Oval gear flowmeter maintenance:

1. When using the flowmeter, check whether the temperature, pressure and flow rate are within the specified range;Whether the pointer rotation is normal, whether the pressure loss is stable, whether the pressure loss is too large, whether the display instrument is normal display;

2.Often check the use of the filter, filter cleaning regularly;

3. When the measured medium contains gas, gas separator should be installed before the flow meter to avoid measurement error;

4. Sweeping steam is strictly prohibited to pass through the flowmeter to avoid damage to the flowmeter;

5.For the measurement of condensate media, then start the flow timing, must preheat the flow meter (the body of the first cover);When the media in the meter into the working state of the liquid, to start the flow rate.

Ⅱ.Check and overhaul the elliptical gear flow meter regularly

1. Check and repair the flow meter regularly, find the worn parts in time, and eliminate trouble spots;

2. If the user verifies the flow meter with the water verification device, the water in the flow meter shall be poured out and the oil wall shall be filled to prevent rust.

Previous :

Liquid flowmeter fault self-testNext :

Common fault of float flow meter