What do you know about the measurement of gas flow?

Gas is (town) artificial gas, is one kind of gas, is at present city dweller and the mainest fuel of many enterprises and institutions.Some are also used as raw materials for chemical products.

In the production, transportation and distribution of gas, there are a large number of gas meters, some for general monitoring, some for trade settlement, including the measurement system for trade settlement, the national standard GB/T17167 has specified its accuracy requirements.

(1)Characteristics of gas flow measurement

a.Low hydrostatic pressure, low flow rate, allowable pressure loss, generally not allowed to reduce pipe diameter to increase flow rate.

b.Fluid humidity is high, and some measuring objects also carry a small amount of water, which flows in layers at the bottom of the pipe.

C.Some measuring objects have high hydrogen content and low fluid density. When measuring with vortex flow meter, the signal is weak.

d.Gas generation furnace, coke oven and other production of gas generally with tar such as viscous substances, some also with a certain amount of dust.

e.When the measuring point is located at the outlet of the compressor, there is a certain flow pulsation.

f.The fluid is flammable and explosive medium, the instrument has explosion-proof requirements.

g.From small to large there are all kinds of pipe paths.

h.The difference between minimum flow and maximum flow is huge.

i.The system used for trade settlement requires high measurement accuracy;As a general monitoring and process control system, the accuracy requirements are lower.

(2)The main contents stipulated by national standards

In 2000, the state administration of quality and technical supervision issued GB/T18215.1 the first part of "measurement of the flow of main artificial gas pipelines in towns", which adopted the method of standard orifice throttle device, and stipulated related technical problems in the measurement of gas flow, including:

①Requirements for fluids: "shall be uniform and single-phase (or may be considered as single-phase) fluids."

②The gas is washed in the process of purification, so the general water content is saturated and the relative humidity is 100%.

③Measurement systems used for trade settlement are generally better than 2.5.The basic error limit is expressed as a percentage of the value.

④Gas flow is defined as the dry part of a wet gas.

⑤Measurement results are expressed in volume flow and converted to standard state.The definition of the standard state in addition to take 101.325 kPa, 20 ℃, and the tradition of the gas industry, also advisable to supply and demand both sides talks things over other temperature, pressure and humidity.

⑥The throttling device adopts multi-tube parallel mode.

⑦In the case of flow pulsation, the following measures are proposed for measuring the average quantity.

a.Adopt attenuation measures in the pipeline, and install filter (composed of vessel and pipe resistance).

b.Keep the instrument away from the pulsating source as far as possible.

c.Using large β and Δp, as far as possible in reducing pipe diameter measurement.

d.Piping and instrument support are installed firmly.

e.The resistance of the two differential pressure tubes is symmetrical.

(3) Type and use of instrument

There are many kinds of flow meters that can be used to measure gas, but few of the ideal meters for measuring gas flow are found, which is mainly determined by the characteristics of gas.The rotary flowmeter is difficult to use because of the existence of viscous substances such as tar.Due to low density and low flow rate, vortex flowmeter is difficult to use.The thermal flowmeter is not ideal due to the variation of water gas and gas composition.Finally, the differential pressure flowmeter has been used for decades to play the leading role.

①Orifice differential pressure flowmeter

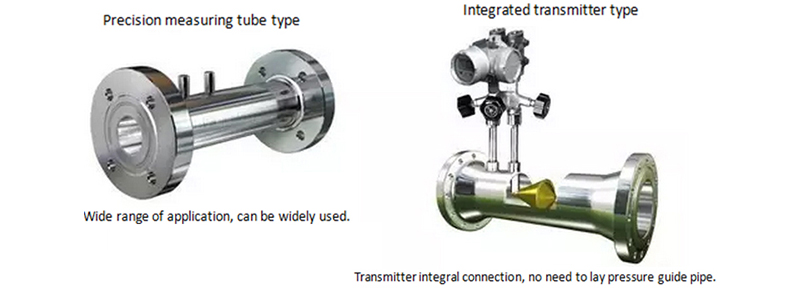

a.Replaceable orifice plate throttling device.

The international GB/ t18215-2000 specification is the standard orifice plate.If the measuring point fluid is dirty, the orifice can be used to throttle the device.Under the condition of continuous air, the throttle can be cleaned, repaired and replaced.The typical structure of the replaceable orifice throttle device is shown in the following figure.

b. Round blank plate.

Circular orifice plate is a special orifice plate designed for the measurement of viscous fluid flow.The hole is part of a circle, which is 98% of the diameter of the pipe.The arc part of the hole should be precisely positioned to be concentric with the pipe.

②Differential pressure flow meter for pitot tube.

Standard orifice differential pressure flowmeter plays an important role in gas flow measurement and has a long history.As this method has rich experimental data, the design and processing has been standardized. As long as it is designed, processed, installed, tested and used in accordance with the standards, the specified accuracy can be achieved without real flow calibration. Therefore, it is very convenient and widely used.However, when the pipe diameter is large, a set of replaceable orifice plate throttling device is of considerable price. Therefore, if the measured data is only used for process monitoring, and the accuracy requirement is not high, then the differential pressure flow meter of the average speed tube can be selected.

The key to successful application of differential pressure flowmeter in gas flow measurement is not to be blocked by water drop.As most of the shutoff valves of the stereotyped equal-speed tube products are needle valves with small sizes and the water in the fluid is condensed into water drops through condensation. If the needle valve is not well handled or the gradient of the pressure tube is not reasonable, the droplet will easily seal the channel.

The differential pressure signal is usually very small.When the fluid is air at room temperature and pressure, if the flow rate is 10m/s, it can only reach 62.5pa differential pressure [28].In this way, a drop of water can seal up the differential pressure transfer channel, enough to cancel out all the differential pressure.Some manufacturers changed the positive and negative pressure cut-off valve into the direct gate valve with larger size, which created the condition for the reliable use of the instrument.