Electromagnetic Flowmeter & Heat Meter

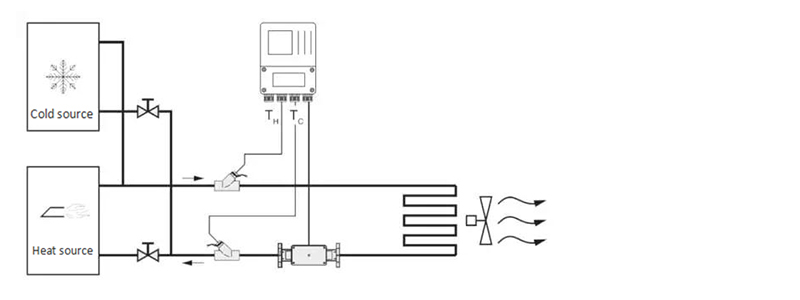

Working principle of heat meter

Heat meter working principle: by heat supply of hot water (cold water) to high (low) temperature into the heat exchange system (radiator, heat exchanger, or by a complex system composed of them), at a relatively low (high) temperature, in the process, to the user through heat exchange heat release or absorption (note: this process include heating system and cooling system energy exchange process).When the water flows through the heat exchange system, the heat released or absorbed by the system is calculated by a calculator based on the flow rate given by the flow sensor and the feed and return water temperature given by the matched temperature sensor, as well as the time of the water flow.

Q=∫qm×τ1τ0Δh×dτ=∫ρ×qv×Δh×dττ1τ0

Q: heat released or absorbed by the system,J or kWh;

qm: mass flow of water flowing through the heat meter,kg/h;

qv: volume flow of water through the heat meter,m3/h;

ρ: density of water flowing through the heat meter, kg/m3;

Δ h: in the inlet and outlet temperature of heat exchanging system water enthalpy difference, J/kg;

τ: time, h.

Measuring principle of electromagnetic flowmeter

The principle of electromagnetic flowmeter is based on Faraday's law of electromagnetic induction.In figure 3 at the ends of the up and down two electromagnetic coil produces a constant or alternating magnetic field, when conducting medium flows through the electromagnetic flow time, flow meter or so two electrodes on the pipe wall can be detected between the induction electromotive force, the size and conducting medium velocity of induction electromotive force, the magnetic induction intensity of the magnetic field, conductor width (flowmeter measurement tube diameter) is proportional to the, then through operation medium flow rate can be calculated out.The induction electromotive force equation is:

E=K×B×V×D

Among them: E- induction electromotive force;

K- instrument constant;

B- magnetic induction intensity;

V- measures the average flow rate in the pipe section;

D- measures the inner diameter of the tube.

Measuring flow rate, fluid flows through the magnetic field perpendicular to the flow direction, fluid flow induction conductivity an induction electric potential is proportional to the average flow velocity, so the measured conductivity is higher than the minimum of the electric conductivity of liquid flow --- 5μs/cm (electromagnetic flowmeter can measure conductivity greater than 5μs/cm theoretically mu s/cm conductive medium, but should guarantee the electromagnetic flowmeter in practical measurement used in the electrical conductivity measured medium in 50μs/cm and above (greater than the theoretical value for one to two orders of magnitude) environment, and must be based on online measurement of electrical conductivity value).The induction voltage signal is detected by two electrodes and sent to the converter by cable. After a series of analog and digital signal processing, the accumulative flow rate and instantaneous flow rate are displayed on the display screen of the converter.

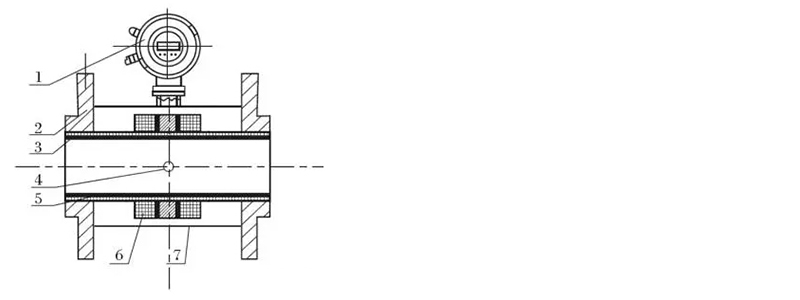

Electromagnetic flowmeter structure

The electromagnetic flowmeter is mainly composed of the following parts:

1-converter;2 - flange;3- insulating lining;4 - electrode;5- measuring tube;6- excitation coil;

7 - housing

The electromagnetic flowmeter is mainly composed of two parts: sensor and transducer. The sensor includes flange, lining, motor, measuring tube, exciting coil and sensor shell.The converter includes the internal circuit board and the converter shell.

(1) Converter: provide stable excitation current for the sensor, and amplify the induced electromotive force obtained through the sensor into standard electrical signal or frequency signal, and display real-time flow rate and parameters, etc., for the display, control and adjustment of flow rate.

(2) Flange: used to connect with process pipes.

(3) Lining: a complete electrical insulating corrosion resistant material on the inside of the measuring tube and on the flange sealing surface.

(4) Electrodes: a pair of electrodes are installed on the wall of the measuring tube perpendicular to the magnetic force line to detect the flow signal. The electrode materials can be selected according to the corrosion performance of the measured medium.Another 1-2 grounding electrodes are installed for flow signal measurement of grounding and anti-interference.

(5) Measuring tube: the measured tube flows through the measured medium.The measuring tube is made of non-magnetic stainless steel welded with flange and lined with insulating lining.

(6) Excitation coil: the measuring tube is equipped with a set of coils on the outside, above and below, to generate the working magnetic field.

(7) Enclosure: it can protect the instrument and seal it.