Blog Categories

Recent Posts

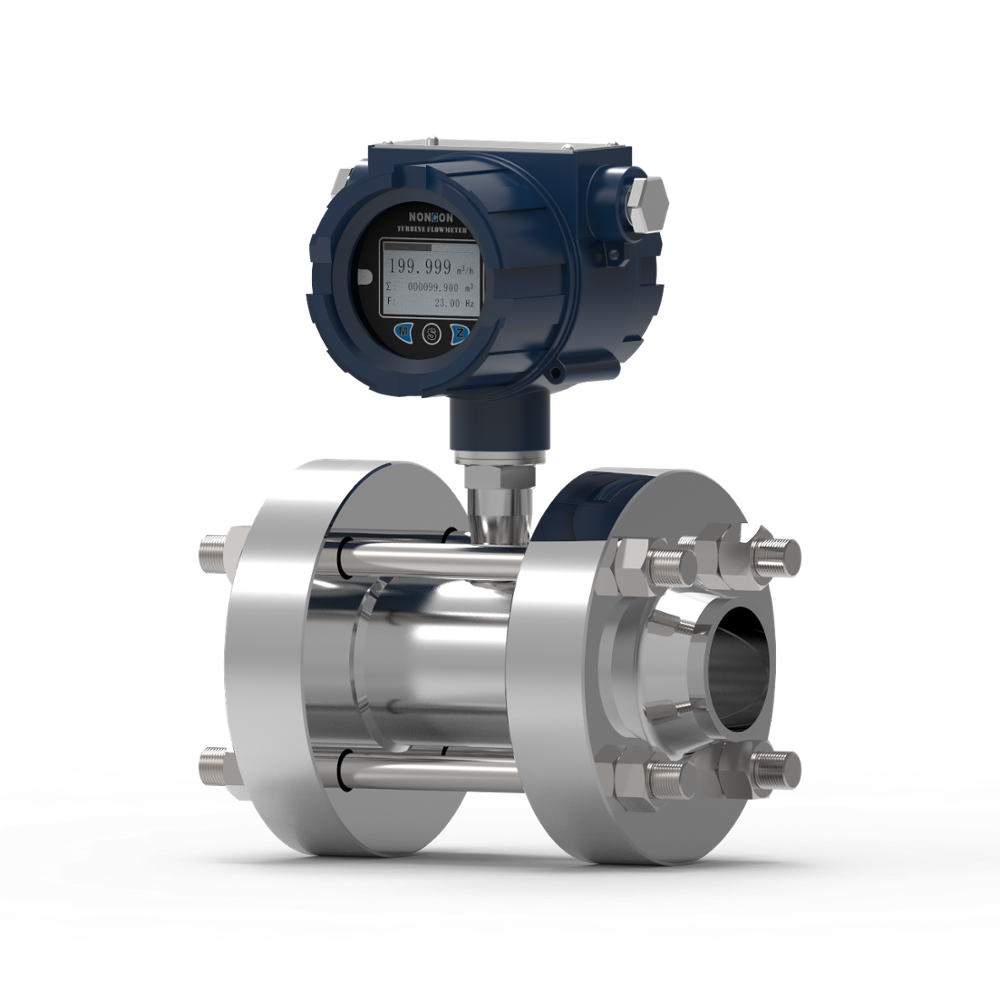

Daily maintenance of pressure transmitter

The transmitter is a converter that converts the output signal of the sensor into a signal that can be recognized by the controller.Transmitters are widely used in factory automation, production process instrumentation and control equipment to measure temperature, pressure, flow,water level and many other process variables.Different physical quantities require different sensors and corresponding transmitters.There are many kinds of transmitters. The transmitters used in industrial control instruments mainly include intelligent pressure transmitter,temperature transmitter, flow transmitter, current transmitter, voltage transmitter and so on.Intelligent pressure transmitter is an indispensable key element in fluid industry. In modern automation industry, intelligent pressure transmitter is widely used, but at present, whether imported or domestic sensors.Damage or other faults may occur due to the instability of the sensor itself or improper operation.In this regard, after purchasing the sensor, the customer should install it in strict accordance with the operation instructions and installation methods on the product manual.In the later stage, the correct maintenance of the sensor is also required. Only the correct maintenance of the pressure sensor can effectively improve the service life and measurement accuracy of the pressure sensor.

This paper mainly introduces the routine maintenance of Noncon instrument intelligent pressure transmitter

Routine maintenance of intelligent pressure transmitter

1. The size of the mounting hole of the intelligent pressure transmitter needs to be checked during installation: if the size of the mounting hole is inappropriate, the threaded part of the sensor is easy to be worn during installation.

2. The following conditions should be considered during the use of intelligent pressure transmitter: prevent the transmitter from contacting corrosive or overheated media;Prevent dregs from depositing in the conduit;When measuring the liquid pressure, the pressure tap shall be opened on the side of the process pipeline to avoid sedimentation and slag deposition;When measuring the gas pressure, the pressure tap shall be opened at the top of the process pipe, and the transmitter shall also be installed at the upper part of the process pipe, so that the accumulated liquid can be easily injected into the process pipe;The impulse pipe shall be installed at the place with small temperature fluctuation;When measuring steam or other high-temperature media, a condenser such as buffer pipe shall be connected, and the working temperature of the transmitter shall not exceed the limit;In case of freezing in winter, anti freezing measures must be taken for the transmitter installed outdoors to avoid the damage of the sensor caused by the expansion of the liquid in the pressure tap due to freezing;When measuring the liquid pressure, the installation position of the transmitter shall avoid the impact of liquid to avoid the damage of overpressure of the sensor;When wiring, pass the cable through the waterproof joint or winding pipe and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

3. Inspection of intelligent pressure transmitter itself: check the use quality of the instrument to achieve accuracy and sensitivity, the indication error and static pressure error meet the requirements, and the zero position is correct;The instrument parts shall be intact without serious rust and damage, the nameplate shall be clear and correct, the fasteners shall not be loose, the connector shall be in good contact, and the terminal wiring shall be firm.

4. Prevent dregs from depositing in the conduit and the sensor from contacting corrosive and overheated media.

5. When measuring the gas pressure, the pressure tap shall be opened at the top of the process pipe, and the sensor shall also be installed at the upper part of the process pipe, so that the bad liquid can be easily injected into the process pipe.

6. When measuring the liquid pressure, the pressure tap shall be opened on the side of the process pipeline to avoid slag deposition.

7. The impulse pipe shall be installed where the temperature fluctuation is small.

8. When measuring the liquid pressure, the installation position of the sensor shall avoid the impact of liquid (water hammer phenomenon) to avoid over pressure damage of the sensor.

9. In case of freezing in winter, anti freezing measures must be taken for the sensor installed outdoors to avoid the loss of the sensor due to the expansion of the liquid in the pressure tap due to icing.

10. When wiring, pass the cable through the waterproof joint or winding pipe and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

11. When measuring steam or other high-level medium, a condenser such as buffer pipe shall be connected, and the working temperature of the sensor shall not exceed the limit.