Blog Categories

Recent Posts

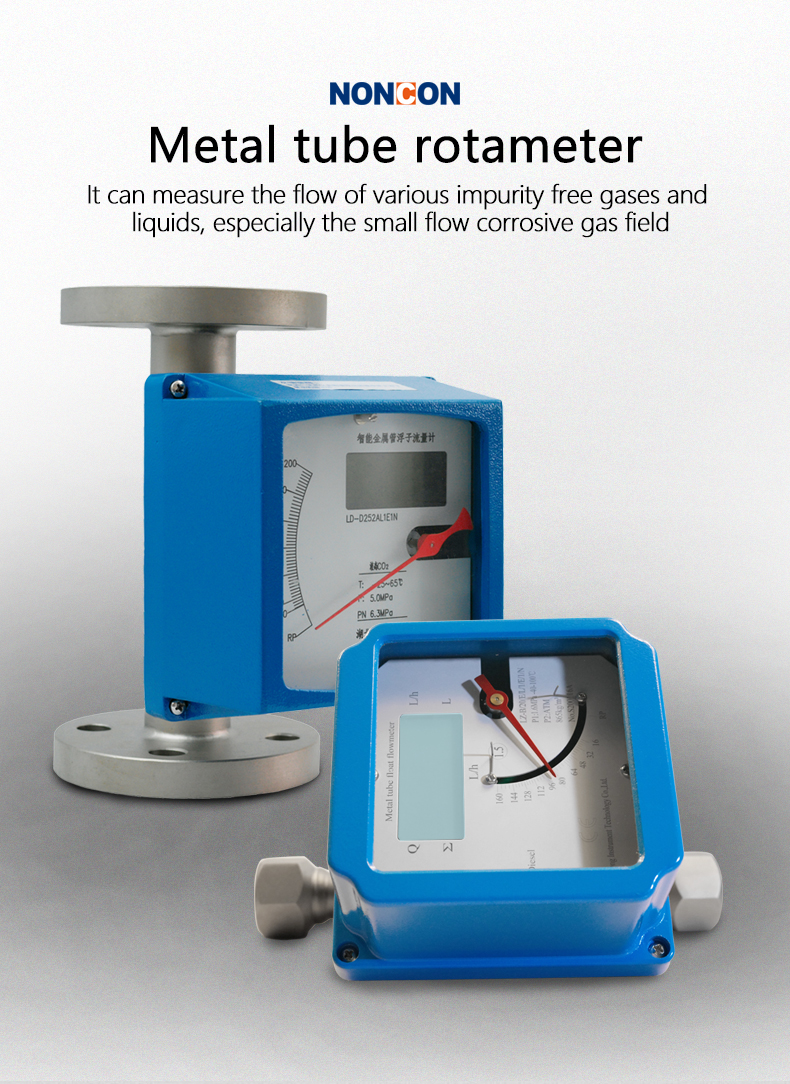

Measurement, Detection and Troubleshooting of Metal Rota meter

The metal rotor flow meter adopts the variable area measurement principle and is suitable for measuring the volume flow of liquid and gas. It is widely used in the flow measurement process of complex and harsh environmental conditions and various medium conditions such as petroleum, chemical, power generation, pharmaceutical, food, water treatment, etc. How to achieve accurate measurement of the flow meter How to make the metal tube rota meter work normally and achieve the required measurement accuracy, pay attention to the following points:

There should be a straight pipe section with a length of more than 5 times the pipe diameter at the inlet of the flow meter, and a straight pipe section of 250mm at the outlet;

The metal tube rota meter should be bypassed,which is convenient for troubleshooting and does not affect production during purging;

If the medium contains solid impurities, it should be considered to install a filter between the valve and the straight pipe section;

The medium contains ferromagnetic substances, and a magnetic filter should be installed;

When the temperature of the measured medium is higher than 220℃ or the temperature of the fluid is too low, crystallization is likely to occur, and when heat insulation protection measures are required, the jacket type should be selected for cooling or heat preservation;

When used for gas measurement, the pipeline pressure should be ensured not less than 5 times the pressure loss of the flow meter, so that the float can work stably;

Pipe flanges, fasteners, gaskets and flow meter flanges have the same standard to enable the normal installation and operation of the instrument;

The flow meter generally does not need maintenance after the device is in normal operation. The fault mostly occurs when the device is just started. Due to the unclean pipeline cleaning, the float is stuck by solid particles, and the pointer of the indicator stops at one position. Do not move. At this time, the valves on both sides of the flow meter should be closed first, then the upper flange should be removed, the float should be taken out for cleaning, and then reinstalled. Note that the tightening of the upper flange nut should be balanced and tightened, and the gasket should be well.

The treatment method for the stuck pointer of the metal tube rota meter:

1. The pointer is stuck

When the metal rota meter is used for the first time, the valve is opened too fast, so that the float quickly hits the stopper upwards, causing the stopper to deform and the float to be stuck. However, it is not excluded that the float is stuck due to the misalignment of the float guide rod and the stop ring. When handling, remove the meter, remove the deformed stopper and reshape it, and check whether it is concentric with the guide rod. If it is not concentric, it can be corrected, then install the float, push the float by hand, and feel that the float is unobstructed up and down. Yes, in addition, when installing the metal tube rota meter, it must be installed vertically or horizontally, and cannot be tilted, otherwise it will easily cause the meter to jam and bring errors to the measurement.

Second, the pointer shake:

1. The pointer shakes slightly of metal tube rota meter: generally caused by medium fluctuation. It can be overcome by increasing damping.

2. Moderate pointer shake: generally caused by the flow of the medium. For gas, it is generally caused by the unstable operating pressure of the medium. A constant voltage or constant flow device can be used to overcome or increase the gas damping of the rota meter.

3. Severe pointer shaking: mainly due to medium pulsation, unstable air pressure or the pressure, temperature and flow rate of the gas operating state given by the user do not match the actual state of the metal tube rota meter, and there is a large difference that causes the rota meter to overrange.