Products

Categories

New Products

Smart gas Roots (waist wheel) flow meter Intelligent gas waist wheel (Roots) flowmeter is a new generation flowmeter that integrates flow, temperature, and pressure detection functions, and can automatically compensate for temperature and pressure. Gas is a compressible fluid, and its volume value is closely related to temperature and pressure. In order to unify standards for both parties, it is necessary to convert the actual volume into a standard volume under reference conditions (101.325 kPa 20°C). In order to achieve this purpose, the smart gas waist wheel flowmeter can accurately correct the volume of gas; it is an ideal instrument for gas measurement in urban gas, petroleum, chemical, electric power, metallurgy and other industries. more

TUF Series Portable Ultrasonic Flow Meter The TUF series ultrasonic flow meter utilizes the principle of low voltage and multiple pulsation time difference, adopts the high-precision and ultra-stable differential transmission of double-balanced signals and differential receiving digital detection technology to measure the acoustic wave transmission time in both the downstream and counter-current directions, and calculates the flow rate according to the time difference.It has the characteristics of good stability, small zero drift, high measuring accuracy and high anti-interference of measuring range over wide. more

LDB Intelligent Type Electromagnetic Flow Meter The LDB intelligent type electromagnetic flow meter consists of a sensor and a converter. It is based on Faraday's law of electromagnetic induction, which is used to measure the volume flow of conductive liquid with conductivity greater than 5μs/cm. It is an inductive meter for measuring the volume flow of conductive medium. In addition to measuring the volume flow of general conductive liquid, it can also be used to measure the volume flow of strong corrosive liquids such as strong acid and alkali and uniform liquid-solid two-phase suspension liquid such as slurry, pulp and paper pulp. more

LKQ Thermal Gas Mass Flow Meter LKQ thermal gas mass flow meter is a mass flow measurement and monitoring meter,which can detect air, natural gas, hydrogen, oxygen, chlorine, nitrogen and ammonia, ammonia, coal gas, phosgene, flue gas and various chemical mixtures, without pressure and temperature compensation. It can be widely used in petroleum, chemical, metallurgy, electric power, water treatment, paper, food, medicine, cement, textile and various production, scientific research units for process control and gas flow measurement. Widely used in: flow measurement of steel plant, coking plant gas. more

LLGQ Gas Roots /Waist Wheel Flow Meter The gas roots flowmeter has been used as a volumetric meter for more than 100 years. With the features such as high precision, wide range, small volume, light weight, convenient installation and maintenance, reliable and durable service life, it is widely used in natural gas, coal gas, air and other gas flowmeters.It is an ideal flowmeter device for urban gas, oilfield chemical, scientific research and other departments at home and abroad. more

High Precision Gas Turbine Flow Meter Gas turbine flowmeter is a new generation of high precision, high reliability gas precision measuring meter integrating temperature, pressure, flow sensor and intelligent flow totalizer developed by the advanced technology of flow meter at home and abroad, optimized by theories of gas mechanics, fluid mechanics and electromagnetics, which has excellent low pressure and high pressure metering performance. more

LUGK Multi Variable Type Vortex Flow Meter Mass vortex flowmeter, simple to install. Connection mode: flange and clamping connection. It has superior reliability and stability due to no movable part, and the detecting portion has only a simple configuration of the vortex generator. Low pressure loss, no leakage point, and high safety performance. Robust sensor construction for high temperature (up to 3500 ° C), high pressure fluid. more

LUGC Steam Gas And Liquid Insert Type Vortex Flow Meter The Insert Type vortex flowmeter is simple in structure and can be made into online installation type.Applicable to large diameter gas, steam flow measurement, etc.Easy installation, no pipe design. more

LUGB Flow Instrumentation Vortex Flow Meter The vortex flowmeter is a speed type flow instrument which has a wide range of uses. It is suitable for flow metering, measurement and control of liquids, steam and most gases. more

High precision, wide range of measurement, small volume, light weight, easy installation and maintenance, reliable use and pressure life and other characteristics of gas Roberts flow meter, widely applicable to natural gas, coal gas, inert gas, air and other gas flow measurement.

Product Origin:

ChinaShipping Port:

Huangpu portLead Time:

SpotMOQ:

1Features

■ It integrates high-precision temperature, pressure, flow sensor and intelligent volume corrector to detect the temperature, pressure and flow of the measured gas and perform automatic flow track and compensation and compression factor correction.

■Use advanced microcomputer technology and high-performance integrated chip, it has powerful functions and superior performance.

■The circuit uses the surface mount technology, with compact structure, strong anti-interference ability and high reliability.

■Pressure sensor, temperature sensor and flow sensor are all built in, making the structure more compact.

■Use advanced micro-power high-tech, the whole machine has low power consumption, that is, it can run with built-in battery for long time, and can be operated by external power supply.

■According to the flow frequency signal, the meter factor can be automatically corrected linearly in five segments, to improve the accuracy of the meter.

■With fault self-diagnosis and alarm function, high reliability, LCD display, clear and intuitive, easy to read.

■The flowmeter has a pulse signal output, and can also output 4~20mA standard analog signal according to user needs.

■The meter has its own real-time database, and through RS-485 communication interface and MODEM, it can form a telephone meter reading network, which is convenient for data collection and real-time management.

■Advanced micro-power consumption technology, low power consumption of the whole machine, using the built-in battery can run for more than five years.

■Display the flow value in place, and with a variety of signal output functions to meet the needs of different sites and systems.

■Use EEPROM data storage chip, save user parameters, manufacturer parameters and certain historical records.

■ Use high-contrast three-line LCD display for displaying date, standard cumulative flow, standard instantaneous flow, medium temperature, pressure, and battery voltage.

■ With real-time data storage function, it can avoid data loss when battery is replaced or suddenly power down. In the power-off state, internal parameters can be permanently saved.

Flowmeter Selection Table 1

|

Model |

Description |

||||||

|

LWGQ- |

□ |

□ |

□ |

□ |

□ |

□ |

Mechanical gas roots flowmeter |

|

LWGQD- |

|

|

|

|

|

|

|

|

Caliber |

25 |

|

|

|

|

|

A:Little range |

|

40 |

B:Big range |

||||||

|

50 |

DN 50mm |

||||||

|

80 |

DN 80mm |

||||||

|

100 |

DN 100mm |

||||||

|

150 |

DN 150mm |

||||||

|

200 |

DN 200mm |

||||||

|

Range |

A |

Little range |

|||||

|

B |

Medium range |

||||||

|

C |

Big range |

||||||

|

Accuracy grade |

01 |

Class 1.0 |

|||||

|

02 |

Class 1.5 |

||||||

|

Output model |

A |

4-20mA two-wire output |

|||||

|

B |

4~20mA three-wire output;Pulse output;RS485 communication (MODBUS protocol);Alarm output |

||||||

|

C |

Pulse output;RS485 communication (MODBUS protocol);Alarm output |

||||||

|

Explosion-proof grade |

N |

Standard type, no explosion-proof |

|||||

|

E |

Explosion-proof type, ExdIICT6 |

||||||

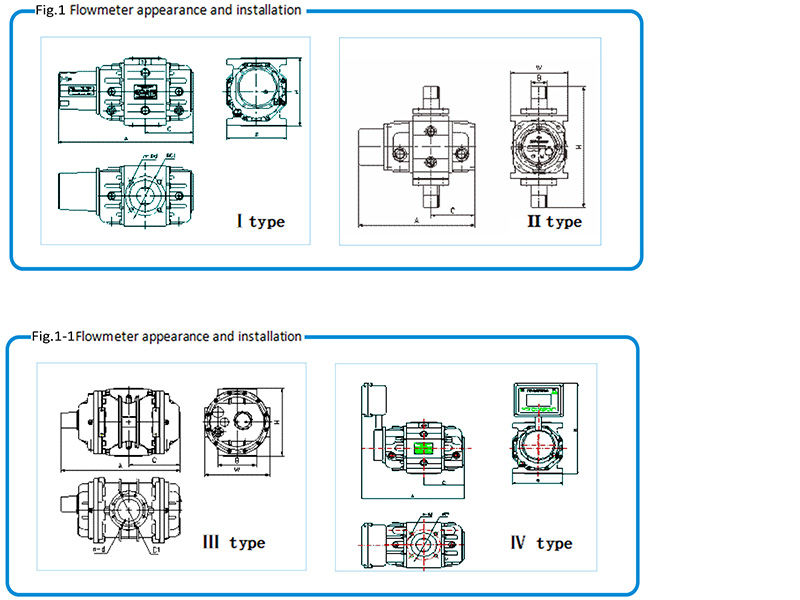

Flowmeter appearance and installation

The flowmeter installation dimensions are shown in Fig.1 and Table 2. The flange is in accordance with GB/T9119-2000.

Table 2 Flowmeter appearance and install dimensions

|

Model specification |

Nominal diameter DN

|

Inlet and outlet direction |

A (mm) |

B (mm) |

C (mm) |

W (mm) |

H (mm) |

Structure type |

Weight (kg) |

Flange |

|

|

C1 |

n-d |

||||||||||

|

LLGQ-20 |

25 |

Entering at top and leaving at bottom |

235 |

G1 |

88 |

105 |

240 |

Ⅰ |

3.5 |

70 |

4-M10 |

|

LLGQ-30 |

40 |

Entering at top and leaving at bottom |

285 |

G1/ |

111 |

105 |

240 |

Ⅰ |

4.6 |

90 |

4-M12 |

|

LLGQ-40 |

40 |

Entering at top and leaving at bottom |

307 |

G1/ |

122 |

105 |

240 |

Ⅰ |

5 |

90 |

4-M12 |

|

LLGQ-60 |

50 |

Entering at top and leaving at bottom |

375 |

167 |

134 |

167 |

190 |

Ⅱ |

12 |

φ110 |

4-M12 |

|

LLGQ-80 |

50 |

Entering at top and leaving at bottom |

375 |

167 |

134 |

167 |

190 |

Ⅱ |

12 |

φ110 |

4-M12 |

|

LLGQ-100 |

80 |

Entering at top and leaving at bottom |

450 |

167 |

169 |

167 |

190 |

Ⅱ |

15 |

φ150 |

4- M16 |

|

LLGQ-150 |

80 |

Entering at top and leaving at bottom |

502 |

167 |

196 |

167 |

190 |

Ⅱ |

17 |

φ150 |

4-M16 |

|

LLGQ-200 |

80 |

Entering at top and leaving at bottom |

465 |

205 |

179 |

235 |

245 |

Ⅱ |

25 |

φ150 |

4-M16 |

|

LLGQ-250 |

100 |

Entering at top and leaving at bottom |

564 |

205 |

230 |

235 |

245 |

Ⅱ |

60 |

φ170 |

4-M16 |

|

LLGQ-300 |

100 |

Entering at top and leaving at bottom |

564 |

205 |

230 |

235 |

245 |

Ⅱ |

60 |

φ170 |

4-M16 |

|

LLGQ-450 |

100 |

Entering at top and leaving at bottom |

655 |

205 |

274 |

235 |

245 |

Ⅱ |

60 |

φ170 |

4-M16 |

|

LLGQ-650 |

150 |

Entering at top and leaving at bottom |

556 |

φ265 |

234 |

450 |

460 |

III |

72 |

φ225 |

8-M16 |

|

LLGQ-1000 |

150 |

Entering at top and leaving at bottom |

696 |

φ265 |

304 |

450 |

460 |

III |

85 |

φ225 |

8-M16 |

|

LLGQ-1600 |

200 |

Entering at top and leaving at bottom |

847 |

φ320 |

380 |

450 |

460 |

III |

90 |

φ280 |

8-M16 |

■ Before selecting the flowmeter, the appropriate model and specifications shall be selected according to the pressure, flow, temperature and process requirements of the metered gas. (see “Flow Conversion”for the calculation method, ).

■ Before installing the flowmeter, the inlet and outlet packages shall be removed. It is necessary to prevent the particulate impurities from entering the measuring chamber. For example, the surface of the measuring chamber is coated with anti-rust oil, which can be cleaned with gasoline or kerosene, and the impurities in the pipe are strictly removed. A filter shall be installed upstream of the flowmeter to prevent rust, welding slag and other impurities from entering the metering chamber.

■When the flowmeter is installed, the rotor axis shall be kept as level as possible regardless of whether the inlet and outlet are vertical or horizontal.

■ When the gas pressure fluctuation range is large, in order to ensure the measurement accuracy, a regulator shall be installed upstream of the flowmeter.

■ In order to prevent rust, welding slag and other impurities in the newly installed pipe from entering the flowmeter, users shall first install the transition pipe on the installation position of the flowmeter.After venting for a period of time, make sure that there are no large particles of impurities, then install the flowmeter. When installing the flowmeter, make sure that the flowmeter center is aligned with the pipe center, no misalignment, and the flowmeter is not affected by external forces (including axial and tangential directions ).

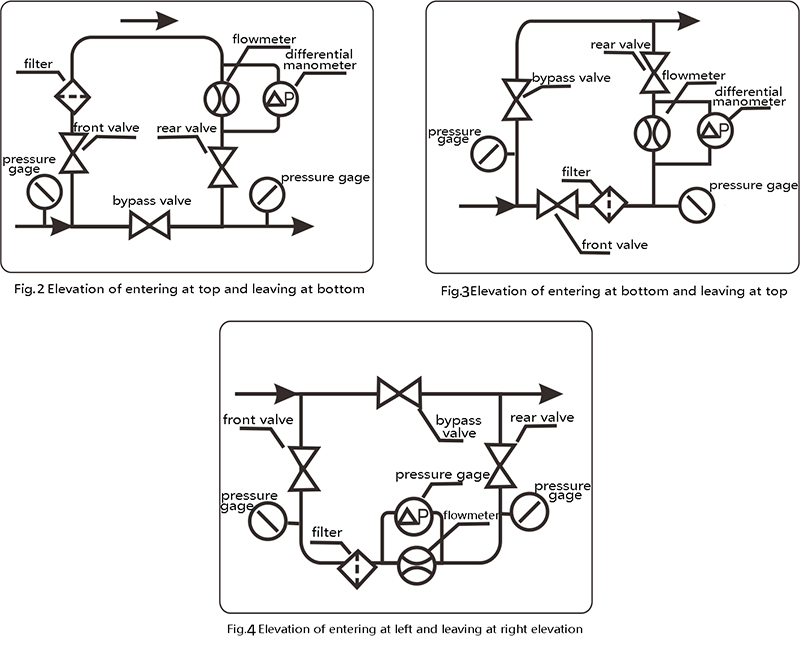

■ When installing the flowmeter vertically. It is recommended that the flow direction of the gas is entering at top and leaving at bottom. In special cases, it can perform entering at bottom and leaving at top,entering at left and leaving at right.However, special descriptions are required when ordering. The standard product of the flowmeter is entering at top and leaving at bottom. The front and rear valves and bypass pipes should be installed when installing the flowmeter to ensure that there is no need to stop the air during maintenance.Fig.2, Fig.3, and Fig.4 show the typical system diagrams for entering at top and leaving at bottom,entering at bottom and leaving at top,entering at left and leaving at right.entering at left and leaving at right.Tpical system diagrams for three flowmeter pipe installation for reference.

■ The pipes and fittings of each part of the flowmeter installation must be properly sized, and the flowmeter body must not be subjected to abnormal external forces.

■ The pipes and fittings of each part of the flowmeter installation must be properly sized, and the flowmeter body must not be subjected to abnormal external forces.

■ After the flowmeter is installed, inject the lubricating oil (GB486~65 high-speed oil H5) from the oil filling port to the oil window center line (note that you cannot add more).

■ Perform regular or irregular inspection during use to ensure sufficient and clean lubricant.If the lubricant is black or the oil level is higher than the center line of the oil window, it indicates the lubricant is deteriorated or has impurities.In this case, replace the lubricant. If the oil level is 3mm below the center line of the oil window, it indicates the loss of lubricating oil and needs to be added to the center line of the oil window. When filling the lubricating oil, it must close the front and rear valves of the flowmeter, and after the gas is drained, then the lubricating oil is added.

■When the flowmeter is in operation, all valves shall be opened and closed slowly to prevent the strong impact of the airflow and damage the flowmeter.

■After the flowmeter is in operation for a period of time, if the pressure drop of the filter is increased, the filter shall be cleaned or the filter medium shall be replaced. If the pressure drop of the flowmeter is increased, and the starting flow rate is increased, and it can flush the metering chamber with clean gasoline or kerosene.

■ When the flowmeter is deactivated for a long time, it should empty the lubricating oil , and the metering chamber shall be flushed with gasoline, then the inlet and outlet shall be sealed and placed in a dry place.

■ When the flowmeter is used to measure city gas (natural gas, artificial gas, etc.), its impurity content shall meet the content standard of China's “Urban Gas Design Code”(GB50028-93).