Products

Categories

New Products

Smart gas Roots (waist wheel) flow meter Intelligent gas waist wheel (Roots) flowmeter is a new generation flowmeter that integrates flow, temperature, and pressure detection functions, and can automatically compensate for temperature and pressure. Gas is a compressible fluid, and its volume value is closely related to temperature and pressure. In order to unify standards for both parties, it is necessary to convert the actual volume into a standard volume under reference conditions (101.325 kPa 20°C). In order to achieve this purpose, the smart gas waist wheel flowmeter can accurately correct the volume of gas; it is an ideal instrument for gas measurement in urban gas, petroleum, chemical, electric power, metallurgy and other industries. more

TUF Series Portable Ultrasonic Flow Meter The TUF series ultrasonic flow meter utilizes the principle of low voltage and multiple pulsation time difference, adopts the high-precision and ultra-stable differential transmission of double-balanced signals and differential receiving digital detection technology to measure the acoustic wave transmission time in both the downstream and counter-current directions, and calculates the flow rate according to the time difference.It has the characteristics of good stability, small zero drift, high measuring accuracy and high anti-interference of measuring range over wide. more

LDB Intelligent Type Electromagnetic Flow Meter The LDB intelligent type electromagnetic flow meter consists of a sensor and a converter. It is based on Faraday's law of electromagnetic induction, which is used to measure the volume flow of conductive liquid with conductivity greater than 5μs/cm. It is an inductive meter for measuring the volume flow of conductive medium. In addition to measuring the volume flow of general conductive liquid, it can also be used to measure the volume flow of strong corrosive liquids such as strong acid and alkali and uniform liquid-solid two-phase suspension liquid such as slurry, pulp and paper pulp. more

LKQ Thermal Gas Mass Flow Meter LKQ thermal gas mass flow meter is a mass flow measurement and monitoring meter,which can detect air, natural gas, hydrogen, oxygen, chlorine, nitrogen and ammonia, ammonia, coal gas, phosgene, flue gas and various chemical mixtures, without pressure and temperature compensation. It can be widely used in petroleum, chemical, metallurgy, electric power, water treatment, paper, food, medicine, cement, textile and various production, scientific research units for process control and gas flow measurement. Widely used in: flow measurement of steel plant, coking plant gas. more

LLGQ Gas Roots /Waist Wheel Flow Meter The gas roots flowmeter has been used as a volumetric meter for more than 100 years. With the features such as high precision, wide range, small volume, light weight, convenient installation and maintenance, reliable and durable service life, it is widely used in natural gas, coal gas, air and other gas flowmeters.It is an ideal flowmeter device for urban gas, oilfield chemical, scientific research and other departments at home and abroad. more

High Precision Gas Turbine Flow Meter Gas turbine flowmeter is a new generation of high precision, high reliability gas precision measuring meter integrating temperature, pressure, flow sensor and intelligent flow totalizer developed by the advanced technology of flow meter at home and abroad, optimized by theories of gas mechanics, fluid mechanics and electromagnetics, which has excellent low pressure and high pressure metering performance. more

LUGK Multi Variable Type Vortex Flow Meter Mass vortex flowmeter, simple to install. Connection mode: flange and clamping connection. It has superior reliability and stability due to no movable part, and the detecting portion has only a simple configuration of the vortex generator. Low pressure loss, no leakage point, and high safety performance. Robust sensor construction for high temperature (up to 3500 ° C), high pressure fluid. more

LUGC Steam Gas And Liquid Insert Type Vortex Flow Meter The Insert Type vortex flowmeter is simple in structure and can be made into online installation type.Applicable to large diameter gas, steam flow measurement, etc.Easy installation, no pipe design. more

LUGB Flow Instrumentation Vortex Flow Meter The vortex flowmeter is a speed type flow instrument which has a wide range of uses. It is suitable for flow metering, measurement and control of liquids, steam and most gases. more

LKQ thermal gas mass flow meter is a mass flow measurement and monitoring meter,which can detect air, natural gas, hydrogen, oxygen, chlorine, nitrogen and ammonia, ammonia, coal gas, phosgene, flue gas and various chemical mixtures, without pressure and temperature compensation. It can be widely used in petroleum, chemical, metallurgy, electric power, water treatment, paper, food, medicine, cement, textile and various production, scientific research units for process control and gas flow measurement. Widely used in: flow measurement of steel plant, coking plant gas.

Product Origin:

ChinaShipping Port:

Huangpu portLead Time:

3~5 Working DaysMOQ:

1Features

■ Direct measurement of mass flow of gas without pressure and temperature compensation;

■High repeatability, high reliability, high stability and high precision;

■Range range width: up to 1000:1 or more;

■Explosion-proof, anti-corrosion design, suitable for harsh conditions, corrosive occasions;

■High sensitivity, especially suitable for flow measurement of large diameter and low flow rate;

■Eextremely small pressure loss and almost negligible;

■Diverse structure, flexible installation, convenient loading and unloading, easy to use, basically maintenance;

■ LCD display, clear and intuitive, showing both instantaneous flow and cumulative flow, so that you can see more clearly and more directly;

Product Classification

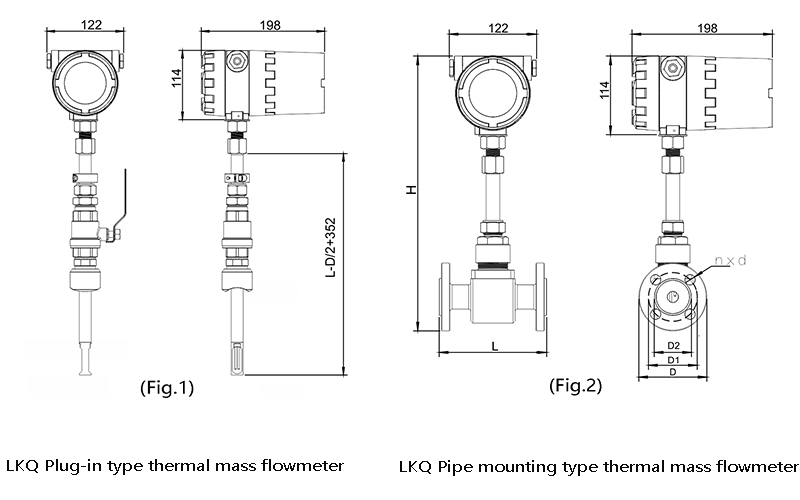

LKQ-A1 plug-in type

Applicable to gas mass flow measurement with pipe diameter greater than DN80. The meter has features such as high precision, good repeatability, high reliability, wide range ratio, fast response, simple and convenient installation, basic free of maintenance, almost no pressure loss, pipe diameter has a very small influence on the price. It has become more and more widely used in the field of gas measurement. Especially after the design with the ball valve installation, it breaks the history that the gas must be shut down when installing the flowmeter on site, which greatly facilitates the use.

LKQ-A2 pipe mounting type

Applicable to gas mass flow measurement with pipe diameter less than DN65. It uses a more beautiful design, with double circlip, ten-layer V-type PTFE gasket, and flange with concave and convex surface, so that the meter will not leak under high pressure, which is more convenient for use, disassembly and maintenance.

LKQ-A2F3 anti-corrosion type

He anti-corrosion type thermal gas mass flowmeter has all the features of the conventional thermal mass flowmeter and the sheath of the sensor is made of special metal material tantalum with good acid corrosion resistance, and in the concentration of 28~29% hydrochloric acid ( at this concentration, hydrochloric acid is the most corrosive to metals.) the wall thickness will be corroded by 4u every year. If the wall thickness of the sheath is to be completely corroded, it takes more than ten years,moreover, the corrosive properties of chlorine, phosgene and other gases actually used are not as corrosive as the concentration of 28, 29% hydrochloric acid solution, and the PBF probe and the pipe to be tested are reliably sealed.

Meter modeling Table 1

|

LKQ |

-□ |

□ |

□ |

□ |

□ |

□ |

□ |

Code description |

|

Installation form |

|

|

|

A1 |

|

|

|

Plug-in type |

|

|

|

|

A2 |

|

|

|

Pipe mounting type |

|

|

Power supply |

|

|

|

B1 |

|

|

|

220VAC |

|

|

|

|

B2 |

|

|

|

24VDC |

|

|

Output signal |

|

|

|

C1 |

|

|

|

4~20mA |

|

|

|

|

C2 |

|

|

|

RS485 |

|

|

|

|

|

C3 |

|

|

|

HART |

|

|

Whether the meter has a display |

|

|

|

D1 |

|

|

|

No display at the meter head |

|

|

|

|

D2 |

|

|

|

Header instantaneous flow display |

|

|

|

|

|

D3 |

|

|

|

Header instantaneous and cumulative flow display |

|

|

Whether it has intelligent flow totalizer |

|

|

|

E1 |

|

|

|

No flow totalizer |

|

|

|

|

E2 |

|

|

|

With intelligent flow totalizer |

|

|

Special requirements |

|

|

|

F1 |

|

|

|

No special requirements |

|

|

|

|

F2 |

|

|

|

Flameproof |

|

|

|

|

|

F3 |

|

|

|

Corrosion resistant (sensor is tantalum material) |

|

|

|

|

|

F4 |

|

|

|

High temperature type (150-250℃) |

|

|

Flowmeter and pipe seal connection |

|

|

|

L1 |

|

|

|

Continuous flow assembly and disassembly device (ball valve) <0.8Mpa |

|

|

|

|

L2 |

|

|

|

Continuous flow assembly and disassembly device (ball valve) + high pressure seal assembly <2.0Mpa |

|

|

|

|

|

L3 |

|

|

|

Simple threaded assembly <0.8Mpa |

|

|

|

|

|

L4 |

|

|

|

Threaded component + high pressure seal assembly <2.0Mpa |

|

|

|

|

|

W1 |

|

|

|

Flange type components >2.0Mpa |

|

|

|

|

|

W2 |

|

|

|

Flange type heat dissipation component (high temperature type) |

|

|

|

|

|

W3 |

|

|

|

The sampling pipe is flanged to the pipe under test on site |

|

|

|

|

|

W4 |

|

|

|

The sampling pipe is threaded to the pipe under test on site |

|

|

Practical pipe diameter |

|

|

|

|

|

|

- |

Based on the actual inner diameter of the pipe at the user site (for example, the inner diameter of the pipe is 300mm, it is indicated by the number 300) |

Installation Dimension and Requirements

Installation dimension(see Table 2)

Table 2

|

Nominal diameter |

Overall dimension |

Flange dimension |

|||

|

DN(mm) |

L(mm) |

H(mm) |

D(mm) |

D1(mm) |

D2(mm) |

|

25 |

125 |

320 |

115 |

85 |

65 |

|

40 |

135 |

345 |

150 |

110 |

84 |

|

50 |

140 |

358 |

165 |

125 |

99 |

|

80 |

194 |

390 |

200 |

160 |

132 |

|

100 |

230 |

410 |

220 |

180 |

156 |

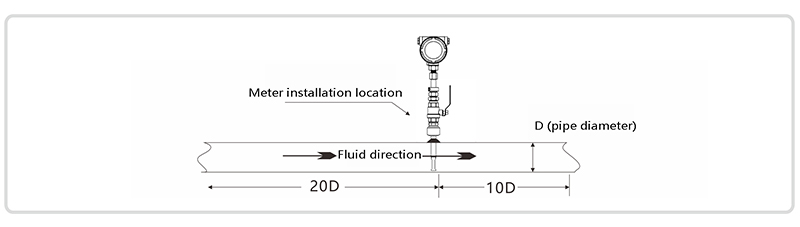

Installation requirements

a. The length of the straight pipe section of the pipe to be tested at the installation of the flowmeter shall meet: upstream 20D distance, downstream 10D distance (D is the inner diameter of the pipe). By using our rectifying flowmeter (pipe diameter ≤ DN100), the length requirements of the front and rear straight pipe sections can be greatly reduced.

b. The flow regulating valve should be installed as least 10D far from downstream of the flowmeter . If it must be installed at the front end, it should be far away from the measuring point.

Previous :

LKQ Thermal Mass Gas Flow meterNext :

LKM Thermal Gas Mass Flow Controller