Blog Categories

Recent Posts

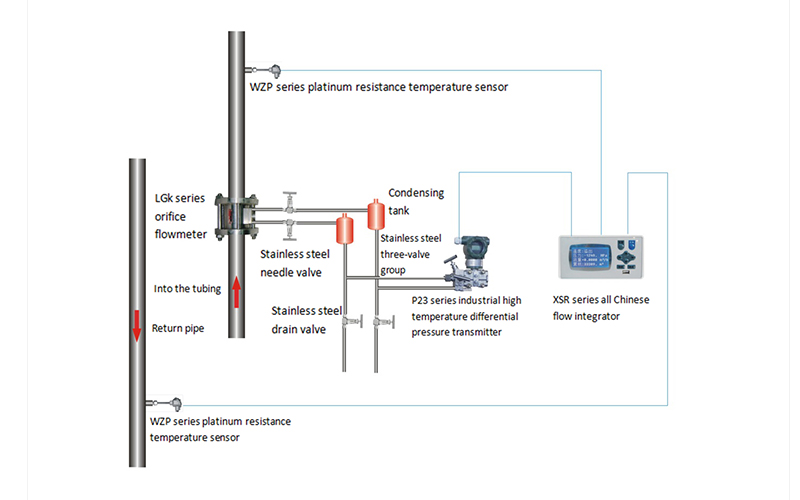

Heat metering system of heat conduction oil furnace

Schematic diagram of heat metering system of heat conduction oil furnace

working principle

Heat conduction oil furnace in heavy oil. Light oil or flammable liquid. Heat conduction oil as heat carrier. Using the circulation pump liquid circulation. After the heat to transfer heat to use equipment. Then return the reheating once-through special industrial furnace. It is widely used in such as petrochemical, textile, printing and dyeing, plastic, rubber, food processing. Wood processing. Asphalt heating. Carton production. Vegetables dehydration. The lacquer that bake. Casting sand mold drying, etc., can also be used for ≤ 350oC baking baking and steaming, finalize the design, melt, and dry.

Heat conduction oil furnace meters and meters are extremely useful

1. Used for combustion safety device.His role is to timely convey information about abnormal conditions in the operation of the equipment, cut off fuel, and safely shut down the equipment.The main instruments are: thermal oil outlet temperature alarm, thermal oil inlet pressure difference detector, flame extinguishing detector, wind pressure detector, fuel pressure detector, gas phase furnace thermal oil pressure detector, fuel cut-off valve, spray media pressure drop detector.Used for combustion safety devices.His role is to timely convey information about abnormal conditions in the operation of the equipment, cut off fuel, and safely shut down the equipment.The main instruments are: thermal oil outlet temperature alarm, thermal oil inlet pressure difference detector, flame extinguishing detector, wind pressure detector, fuel pressure detector, gas phase furnace thermal oil pressure detector, fuel cut-off valve, spray media pressure drop detector.

2. Instruments for combustion control.The main ones are: heat conduction oil temperature control meter at the outlet of heating furnace, flash tank pressure regulator, combustion flow regulator, combustion air flow regulator, combustion oil media pressure difference regulator, gas phase furnace flash tank liquid level regulator.

3. Instruments for operation monitoring.The main ones are: furnace outlet pressure gauge, heat conduction oil circulation pump inlet and outlet pressure gauge, burner internal pressure gauge, expansion tank level meter, soot concentration meter, oxygen concentration meter, etc.High degree of automation of heat conduction oil furnace, quick start and stop, safe and reliable operation;High thermal efficiency, stable output, strong load adaptability;Compact structure, small size, small footprint;Less auxiliary machines, simple and convenient installation, short installation cycle;With sufficient fuel combustion and less pollutant emission, it can achieve a higher environmental protection index. Therefore, it is an ideal green environmental protection product with high efficiency, low consumption and low pollution.

Product features of heat conduction oil furnace

1. Can run at low pressure, high working temperature, can be used as below 500 ℃ high temperature heat source.

2. Stable heating temperature, accurate load-temperature adjustment, stable operation within the adjustable load section, automatic operation control and safety monitoring device.

3. Closed cycle heating, high heat utilization efficiency, significant energy saving effect.

4. Molten salt is solid at room temperature, so it must be preheated before starting, and all molten salt in the system must flow back into the storage tank when stopping, so it is more complicated to start and stop.