Blog Categories

Recent Posts

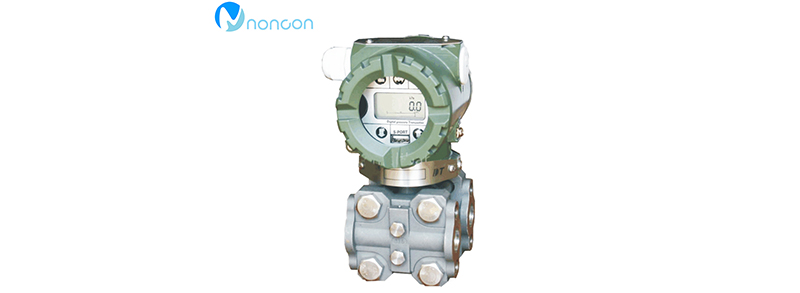

Instrument necessary: pressure transmitter selection and installation strategy

Pressure instrument is a very important parameter in modern industrial production.Pressure, temperature, flow together and known as the three elements of industrial automation control.Therefore, in order to ensure the reasonable and reliable application of pressure transmitter, it must be reasonable selection and correct installation.The following content for you to bring pressure transmitter in the selection and installation of the relevant information.

Main selection basis

1. Measuring medium

If you are measuring a relatively clean fluid, use a standard pressure transmitter.If the medium under test is highly viscous and prone to crystallization and strong corrosion, the isolated transmitter must be selected.In the selection to consider the medium of its metal box corrosion, must choose the box material.

2. Range of measurement

From the choice of transmitter measurement range, the general transmitter has a certain range adjustable range, the best range will be used in its range of 1/4~3/4 section, so the accuracy will be guaranteed, for differential pressure transmitter is more important.

3. Accuracy level

Each kind of gauge can have precision error, the accuracy grade that each country place marks is different, if accuracy of European mark is 1%, accuracy of Chinese mark is 0.5%.

4. Liquid connection material

The contact medium of the pressure transmitter is made of 316 stainless steel. If the measuring medium is corrosive to 316 stainless steel, chemical seal should be adopted to protect the pressure transmitter and extend its service life.

5. Output signal

There are many kinds of output signals of the pressure transmitter, including 4~20mA, 0~20mA, 0~10V, 0~5V, etc. The commonly used ones are 4~20mA and 0~10V. Only 4~20mA signals are of two-wire system, while the others are of three-wire system.

6. Medium temperature

The signal of the pressure transmitter is partially converted through the electronic circuit. In general, the measured medium temperature of the pressure transmitter is -30 to +100 degrees.If the temperature is too high, it is generally used to cool the medium by condensation bending.

7. Other

After determining the above parameters, the process connection interface of the pressure transmitter and the power supply voltage of the pressure transmitter should also be confirmed.If it is used in special occasions, explosion protection and protection level should be considered.

Preparation before installation

1. Check the equipment: since the equipment provided is different from the design supplier and model, it is necessary to determine the transmitter corresponding to each bit number according to the range, design and installation mode, and the material required by the process medium.

2. Determine the installation location: the pressure transmitter of various series should adopt waterproof and dustproof structure, and can be installed in any place.However, from the aspects of facilitating daily operation and maintenance, extending service life and ensuring reliability, the installation location has the following requirements:

(1)There is enough working space around, and the distance from the adjacent object (in any direction) is greater than 0.5m;

(2)There is no serious corrosive gas around;

(3) Not exposed to the surrounding thermal radiation and direct sunlight;

(4)To prevent the transmitter and pressure guide tube (capillary) vibration on the output interference, the transmitter should be installed in a place without vibration.

Correct installation of pressure transmitter

1. Selection of pressure point

(1)The selected pressure measuring point should reflect the real size of the pressure under test.Pressure point should be selected in the straight flow of the pipe section of the medium under test, not in the pipe bend, bifurcation, dead Angle and easy to form vortexes.

(2)For the gas medium, a small amount of condensate in the gas body should flow back to the process pipe smoothly, so the pressure point should be in the upper half of the pipe;For liquid and liquid media, a small amount of gas precipitated from the liquid should be returned to the pipe, and impurities and particles in the pipe should be prevented from entering the measuring pipe and instrument, so the pressure point should be in the lower half of the pipe, but not in the bottom of the pipe.

2. Pressure guide pipe laying

(1)The thickness of the pressure guide pipe shall be appropriate, the general inner diameter of 6~10mm, the length shall be as short as possible, the longest shall not exceed 50m;

(2)The pressure guide pipe shall be installed horizontally with a gradient of 1:10-1:20 to facilitate the discharge of liquid (or gas) accumulated in the pipe;

(3)A globe valve should be installed between the pressure outlet and the manometer to facilitate the maintenance of the pressure transmitter.

3. Determination of installation point

(1)The transmitter should be installed in an easy to observe and repair place.

(2)The installation site should try to avoid the impact of vibration and high temperature.

(3)When the test liquid, steam temperature above 60℃, on-site installation of pressure transmitter take source components shall be equipped with circular bending or u-shaped condensation.