Blog Categories

Recent Posts

Previous and present life of the coriolis mass flowmeter

Coriolis mass flowmeter, together with turbine flow meter and volumetric flow meter, is one of the three types of flowmeter with the best repeatability and accuracy.This flowmeter has good reliability, long service life, and can measure the flow rate of high viscosity fluid and high pressure gas, because there are no blocking elements and movable parts in the fluid passage.Because of these advantages, coriolis mass flowmeter is being used more and more widely in all kinds of process industries. Even this kind of flowmeter is called a profound change of measurement technology.

The coriolis mass flowmeter, of course, is based on the coriolis force principle.

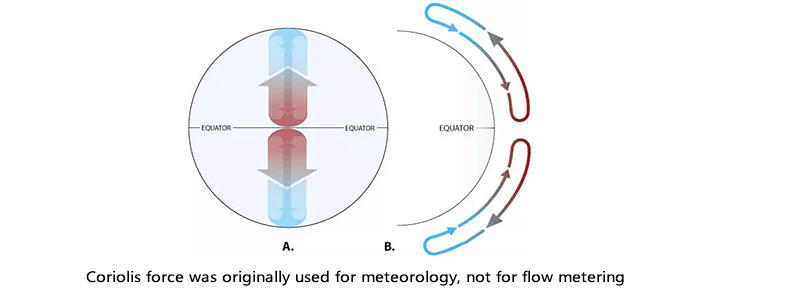

The coriolis force is based on Newtonian mechanics.In 1835, French meteorologist and engineer coriolis proposed that in order to describe the motion of a rotating system, an imaginary force should be introduced into the equation of motion, which is called the coriolis force.With the introduction of coriolis force, the equation of motion in a rotating system can be treated as simply as the equation of motion in an inertial system.Since the earth itself was a huge rotating system, the coriolis force was soon used successfully in the field of fluid motion.

In his original research, coriolis did not involve any applications, but only discussed the energy conversion and conservation in the rotational system.In 1835, coriolis published his most famous paper, equations for the relative motion of multibody systems.In this paper, coriolis mathematically gives the inertial force in a rotating system and classifies it as a component of centrifugal force, which is called "compound centrifugal force" and the original centrifugal force is called "ordinary centrifugal force".This "compound centrifugal force" as opposed to centrifugal force is now known as the coriolis force.

The term "coriolis force" was not used until the early 20th century.Today, however, the name of coriolis is inextricably linked to meteorology and to the most accurate flowmeter in our instrumentation profession.

The world's first flowmeter based on the coriolis force principle appeared in the late 1970s, which is recognized in the industry as being developed by the United States with high accuracy (currently belonging to Emerson).

The coriolis mass flowmeter mass measurement principle is: when the fluid flows in the vibration tube, will produce the coriolis force which is proportional to the mass flow rate.When there is no fluid flow, the vibration tube does not produce distortion, and the signal detected by the electromagnetic signal detectors on both sides of the vibration tube is in the same phase.When a fluid passes through, the vibrating tube will distort under the action of torque, and there will be phase difference between the two detectors.The transmitter measures the lag time between the left and right detection signals, which is multiplied by the flow calibration coefficient to determine the mass flow.The density measurement principle of coriolis mass flowmeter is that the vibration frequency is inversely proportional to the square root of the fluid density, and the fluid density is determined by measuring the vibration frequency.

So in daily use, how to use the coriolis mass flowmeter?

Technical indicators

There are many technical indicators of coriolis mass flowmeter, among which the most important is the zero point stability, because the zero point stability will affect the basic error linearity, repeatability, accuracy and long-term stability of coriolis mass flowmeter and a series of performance.Of course the maximum flow and the pressure loss at the maximum flow are also very important, which is related to the true performance index of coriolis mass flowmeter.

Attention during installation

First, because of the mass flowmeter is produced by fluid flowing through the pipeline vibration of coriolis principle to achieve the goal of measuring, so the installation of the mass flowmeter status should be no stress state, the flow meter installed shall be the line on the same axis, and should be near the mass flowmeter sensor for support or clamp, sensor must not be used to support the pipeline, which can eliminate the vibration noise, reduce the error.

Secondly, the installation site should be far away from the large transformer or motor, because the cable connecting the sensor and the transmitter is covered or close to the electromagnetic field emitted by such as the motor, which will cause interference and make the reading inaccurate and produce errors.

Finally, the installation shall be oriented according to the different properties of the fluid, that is, the fluid in the sensor tube shall be kept in a full state at all times.

Attention during debugging

First of all, visual inspection should be carried out to ensure that the appearance of the coriolis flowmeter is free from damage, rust, looseness and displacement, whether it is installed in the correct position, and whether it is convenient for subsequent operation and maintenance.

Secondly, the continuity and insulation of the coriolis meter control cable and power cable should be checked to meet the requirements of the commissioning program.

Thirdly, the parameters of the coriolis flowmeter should be set: the basic parameters, including mass flow unit, upper and lower limit and time constant, should be set through the operation panel.Attention should be paid during parameter setting: the installation coefficient of the mass flow meter should be consistent with the product specification when it is filled with water;In addition, before zero to ensure that the pipe is fully filled with media, the pipe needs to discharge gas, and zero to ensure that the media completely stop flow.

Influencing factor

(1) Influence of temperature

As a result of the measurement is a fluid mass flow rate, so the actual temperature change has no effect on the quality, but when the fluid temperature change will affect the stability of the instrument zero, so when the fluid temperature changes also affect will produce a certain accuracy, so according to actual operating temperature of zero calibration, in order to achieve the purpose of reduce error.

The temperature will also affect the viscosity of the medium. If the pressure drop increases when the fluid passes the instrument due to the increase of viscosity due to the decrease of temperature, the circulation condition of the medium will be affected. This situation can be controlled by the form of thermal insulation.

(2)Influence of pressure

Process can be ignored the influence of pressure on the liquid flow rate, but when the work pressure is below or above the pressure, the vibration of the sensor tube will produce a forward or reverse error, this happens in the function, the more obvious when the sensor diameter is larger, so also cannot ignore, this method can be used with external pressure transmitter to flow.