Blog Categories

Recent Posts

Understand vortex flow meter: only 3 minutes

Vortex flow meter appeared later than other flowmeters.However, since its application in 1970s, vortex flowmeter has developed rapidly.According to the data, at present, the proportion of vortex flow meters used in the world's major developed industrial countries has increased significantly, and they have been widely used in various fields, and will even play a leading role in the future flow meters.So what's so amazing about this flow meter?What should I pay attention to when using it?

Vortex Flowmeter principle

All vortex flowmeters are based on kamen vortex principle, so what is the specific situation?

Karman vortex is a phenomenon observed and studied by Hungarian scientist von karman in 1911: when the fluid goes around a non-fluid linear object, the two sides of the object wake produce pairs of antisymmetric vortices, which are alternately arranged and rotate in opposite directions.In kamen vortex street, according to strauhal's study, the relation is Sr=fd/V, that is to say, for the flow around a cylinder, the frequency f of each single vortex in the vortex street is directly proportional to the flow velocity V, and inversely proportional to the diameter of the cylinder.Sr is strauhal constant and dimensionless, which is related to the shape and Reynolds number of the vortex generating body.

Vortex flowmeter is not a turbine flowmeter

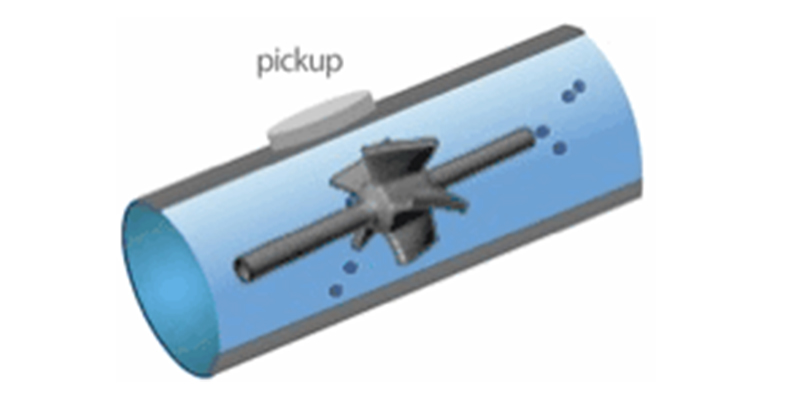

In everyday applications, some people confuse vortex flowmeters with turbine flow meters. After all, the name is very similar.So what is a turbine flowmeter?The following figure is part of the turbine flowmeter pipe:

Obviously, it can be seen that there is a great difference between turbine flowmeter and vortex flowmeter. This flowmeter is measured by rotating the turbine in the pipeline driven by fluid, and its structure is much more complex than that of vortex flowmeter.Such a complex structure brings the best accuracy of flowmeter, but also brings the disadvantages of easy damage and complex maintenance.

Advantages and limitations

What are the advantages and limitations of vortex flow meter?What is the outstanding quality that makes vortex flow meters develop so rapidly and occupy a large number of markets?

Advantages

1. the structure is simple and firm, no moving parts, high reliability, long-term operation is very reliable;

2. Simple installation and convenient maintenance;

3. The sensor does not directly contact the media, with stable performance and long service life;

4. High accuracy (compared with differential pressure type and float type);

5. Wide measuring range, with a range ratio of 1:10;

6. Less pressure loss, lower operating cost and more energy-saving significance;

7. Within a certain Reynolds number range, the output signal frequency is not affected by fluid physical properties and component changes. The instrument coefficient is only related to the shape and size of the vortex generating body;

8. Wide application range, the flow of steam, gas and liquid can be measured.

Limitations

1. Uneven pipeline flow rate, inability to accurately determine the medium density when fluid conditions change, assumption of wet saturated steam into dry saturated steam for measurement will cause errors, and the total measurement error will be large.

2. Poor seismic performance, external vibration will lead to measurement error of vortex flow meter, or even failure to work normally, and the influence of large pipe diameter is more obvious.

3. Poor adaptability to dirty media measurement.

4. High requirements for straight pipes.Experts pointed out that the branch pipe of vortex flowmeter must ensure the first 40D and the second 20D to meet the measurement requirements.

How to make good use of vortex flow meter?

After selecting vortex flowmeter, the first problem to be faced is the installation of vortex flowmeter.So what do you need to pay attention to when installing?

(1) The flowmeter shall be installed horizontally or vertically on the pipeline corresponding to the passing of the project.Due to the characteristics of vortex flow meter, it is necessary to ensure the measurement of slow pipe in order to achieve accurate measurement. Therefore, vortex flow meter on horizontal pipe should be installed at the lowest place in the pipe. In vertical pipe, the flow direction of fluid should be from top to bottom.

(2) When the vortex flow meter is used for flow regulation, special attention should be paid to installing the flow control valve behind the flow meter, otherwise, jet flow is likely to occur when the flow is small, and the flow up to the time of flow regulation is inversely proportional to the valve opening.

(3) Vortex flowmeters have very strict requirements on front and rear straight pipes. The upstream of the flowmeter should be guaranteed to have 10 to 40 times the pipe diameter, and the downstream not less than 5 times the pipe diameter.The length of the upstream straight pipe is determined by whether the upstream has right-angle bend, expansion or reduction pipe.In particular, it should be noted that, in the case of satisfying the requirements, the flow meter should be installed in the front and rear straight pipe section as large as possible at the location of the pipeline.

(4) To measure the temperature and pressure of the temperature \ pressure point should be set in the vortex flow meter outlet 5 calibre accident.

(5) When installing vortex flowmeter, strong vibration and power-frequency interference signals should be avoided as far as possible. If these conditions cannot be avoided, shock absorption, shielding and other measures should be taken to minimize interference.

(6) In high-temperature pipelines, vortex flow meters must be installed vertically downward.

Daily maintenance

Vortex flowmeter has no moving parts, so the maintenance work is less in normal use.Daily maintenance task is: check whether the accumulation of instrument indicators is normal;Check whether the power supply of the instrument is normal;Check whether the connector of instrument body is damaged and corroded;Check whether there is any damage or corrosion to the external circuit of the instrument;Check whether there is leakage at the connection between the surface body and the process pipe;Check whether the junction box and electronic component box are sealed well.

When the measured medium is dirty or easy to scale, the inner wall of the flowmeter should be cleaned regularly. The vortex generating body and the detection probe should be protected during cleaning, and the surface and edges should not be damaged.The end cover of the detection amplifier housing should be properly tightened after wiring debugging to ensure its tightness.Do not leave liquids and sundries in the shell during maintenance inspection.