There are three common problems with rotameter

Flow meter is now an essential product in the industry, there are many types of flowmeter, such as: rotor flowmeter, electromagnetic flowmeter, vortex flow meter, turbine flow meter.Under each category of flowmeters can be divided into a number of small flowmeter categories.If rotor flowmeter can be divided into glass rotor flowmeter, metal tube float flowmeter, plastic tube float flowmeter, micro flow flowmeter and so on.

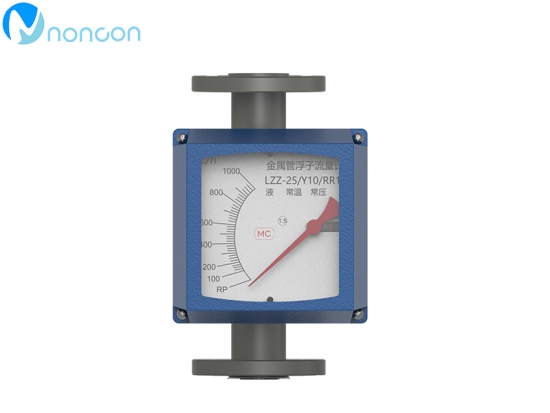

Rotameter, also known as the float flowmeter is a kind of according to the variable area flowmeter, the liquid in the flowmeter calibration tube flowmeter, bottom-up, fluid buoyancy and upward lift lead float up, reach a balance, but and gravity float remain stable, flow indicator scale at this time is the real traffic flow.

However, the rotameter sometimes fails. There are three common types:

1. Large measurement error of rotor flowmeter:

1). As the gas medium is greatly affected by temperature and pressure, it is recommended to adopt the method of temperature and pressure compensation to obtain the real flow rate.

2). Due to long-term use and pipe vibration and other factors, the sensor magnetic steel, pointer, counterweight, rotating magnetic steel and other moving parts of the float flowmeter become loose, resulting in a large error.

3). The installation does not meet the requirements: for the vertical installation of the rotameter, the vertical tilt Angle shall not be greater than 20 degrees;For the horizontal installation of rotameter to keep horizontal, tilt Angle is not greater than 20 degrees;No ferromagnetic objects are allowed in the space of 100mm around the rotameter.Install away from valve orifice, pump outlet, process pipeline turn port, etc.The requirements of the first 5D and the second 250mm straight pipe segment shall be maintained.

4). The large density variation of liquid medium is also a cause of the large error.

2, rotor flowmeter pointer jitter:

1). Slight pointer jitter: generally caused by medium fluctuation.This can be overcome by increasing damping.

2). Moderate pointer jitter: generally caused by the flow state of the medium.For gas generally due to medium operating pressure instability.Stable pressure or steady flow device can be used to overcome or increase the gas damping of the rotameter.

3). Violent pointer jitter: mainly due to medium pulsation, air pressure instability or the pressure, temperature and flow rate of the gas operation state given by the user are inconsistent with the actual state of the rotor flowmeter, resulting in a large difference in the range of the rotor flowmeter.

3. The pointer of the rotameter stops at a certain position and does not move:

The main reason is that the rotor of the rotameter is stuck.Generally, the rotor flowmeter opens the valve too fast when it is used, which causes the rotor to impact the stopper up rapidly, causing deformation of the stopper and the rotor to be stuck.However, it is not ruled out that the rotor is stuck due to the different centers of the rotor guide rod and the stop ring.Processing instrument can be removed, the deformation of plastic surgery to stop off, and check whether with guide bar work, such as different heart can be calibrated, then the rotor installed, push the rotor, feeling the rotor unimpeded card can be up and down, in addition, the rotor flowmeter installation must be vertical or horizontal installation, cannot tilt, otherwise easy to cause the card table, and also brings to the measurement error.